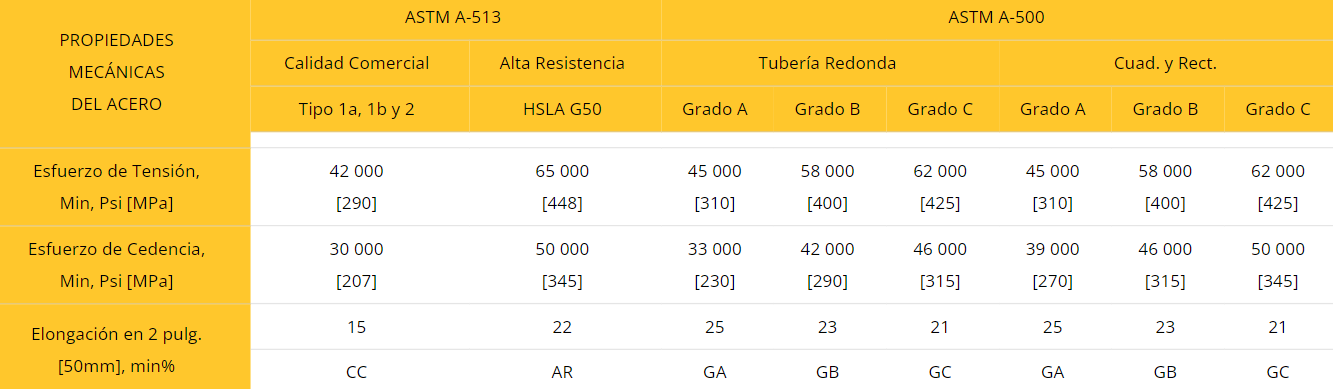

STANDARDS

We certify our products based on the ASTM (American Society for Testing and Materials) regulations; we guarantee their dimensions and properties.

For raw materials

- Hot rolling: ASTM A 1011

- Cold rolling: ASTM A 1008

- Galvanizing: ASTM A 653

For tube manufacturing

- ASTM A 500

- ASTM A 513

- ASTM A 787

* : Typical Values.

1a: A.W.H.R. “as welded” from hot-rolled steel (with mill scale).

1b: A.W.P.O. “as welded” from hot-rolled pickled and oiled steel (mill scale removed).

2: A.W.C.R. “as welded” from cold-rolled steel.