PRE-PUNCHED ROLL FORMING

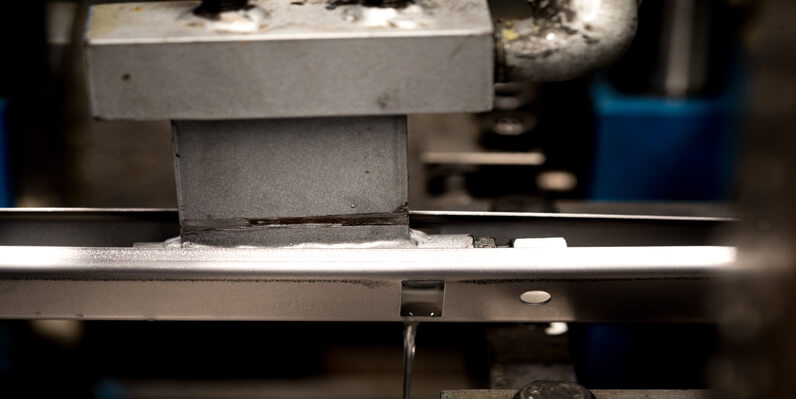

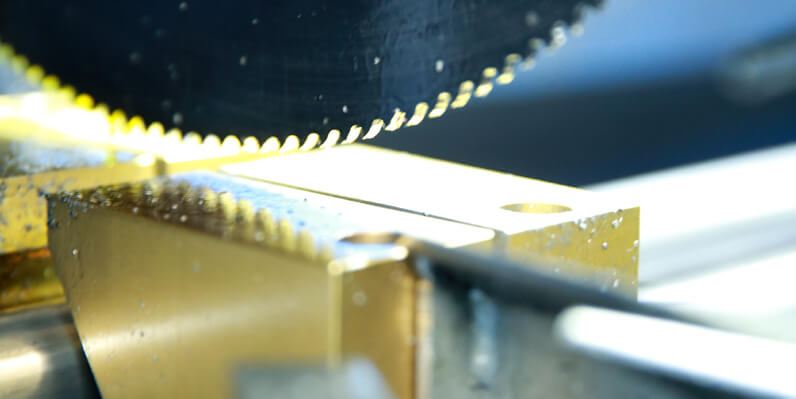

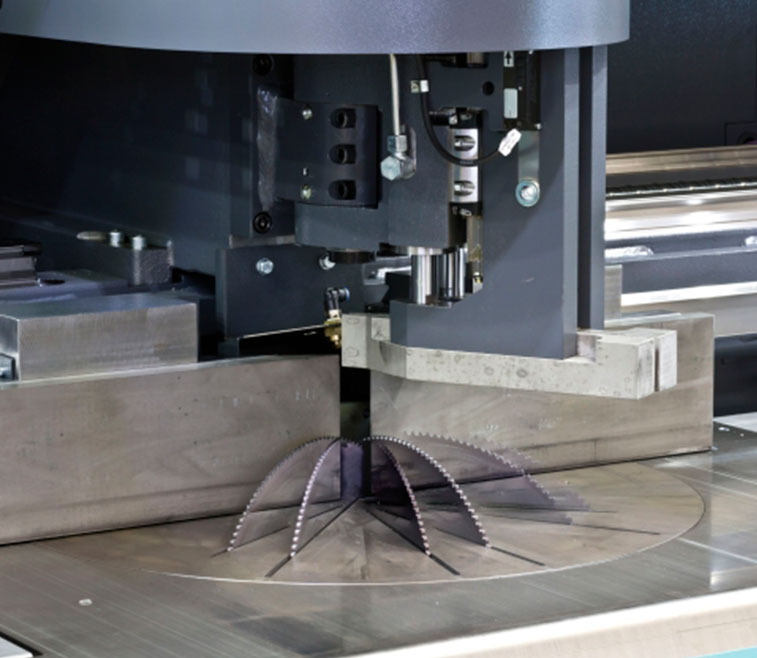

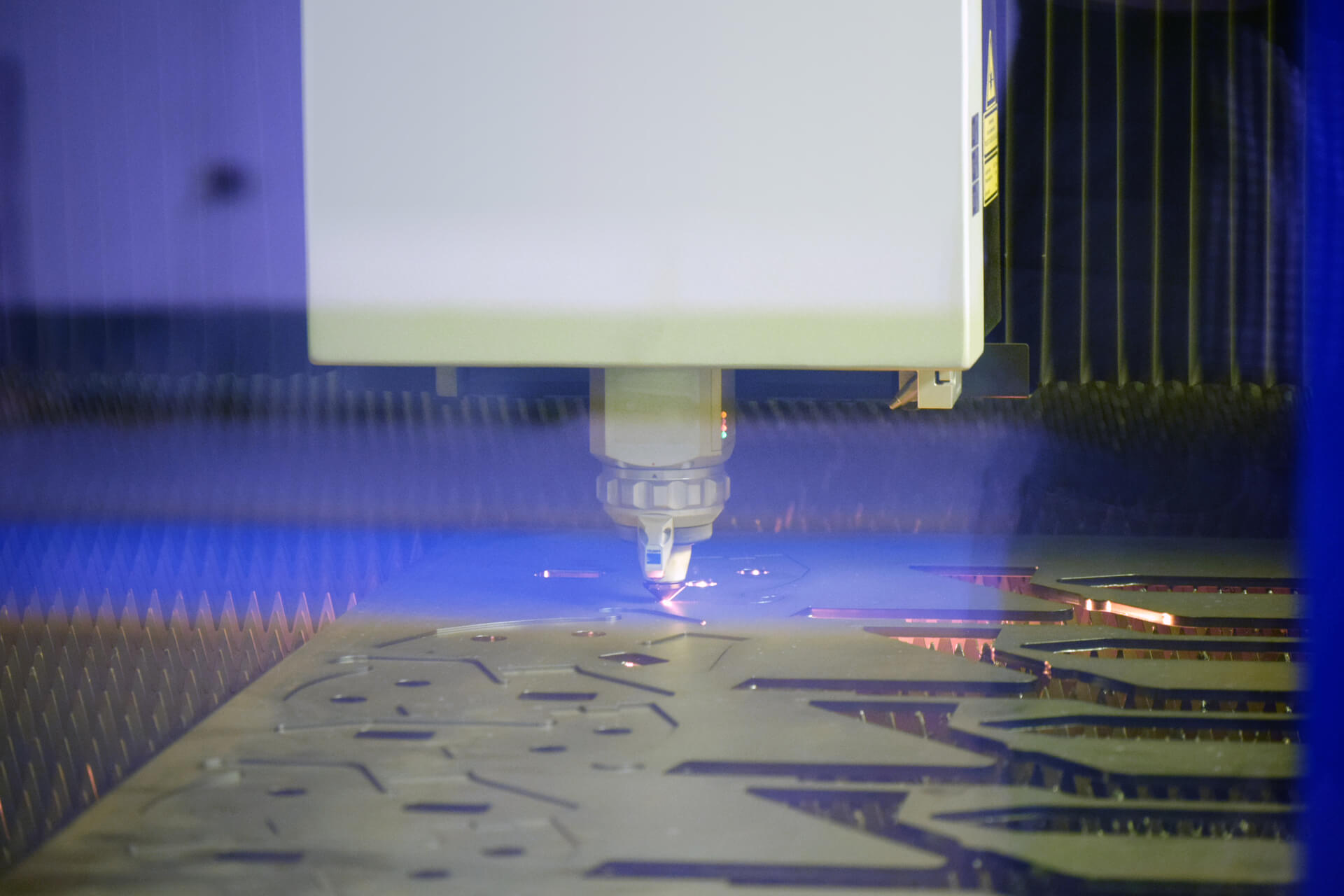

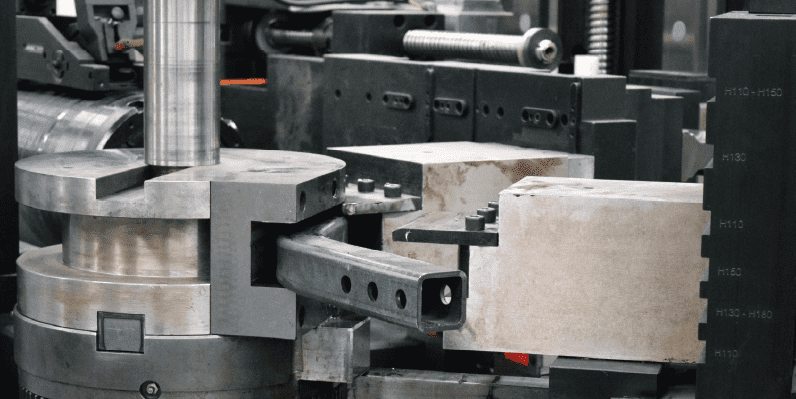

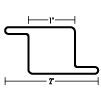

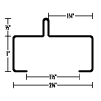

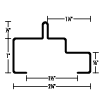

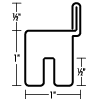

The pre-punched roll forming mill punches the steel sheet according to the requirements of each project while giving shape to the tube.

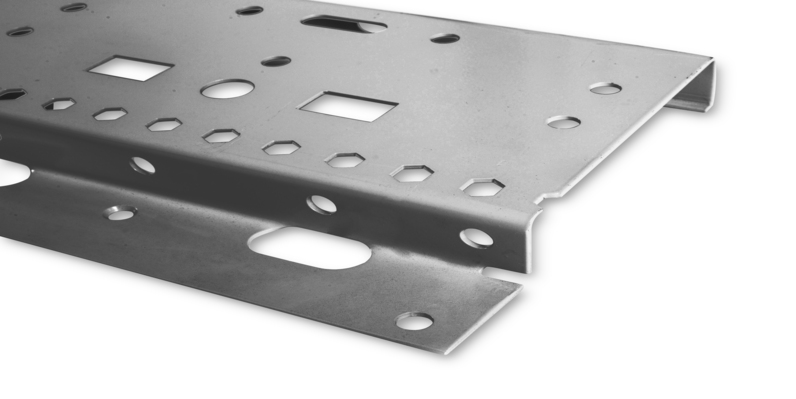

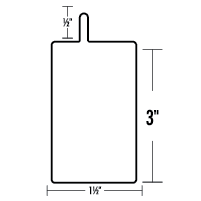

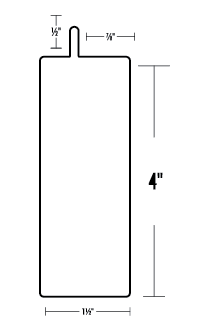

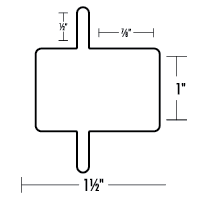

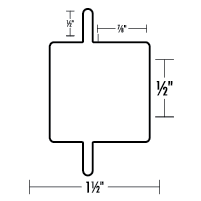

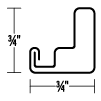

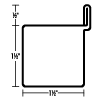

The pre-punched roll forming mill is a machine which is fed with carbon steel coils that are punched according to the requirements of each client and project before being processed by the forming tools. This process reduces production times and allows infinite design options. Pre-punching gives versatility to our tubes and shapes in order to adapt to any project.

At PROLAMSA we have a pre-punched roll forming mill capable of reproducing any design and drilling pattern to satisfy the client’s needs. This equipment can process specialized steel with tensile strength up to 1500 MPa (Megapascals).

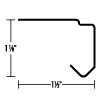

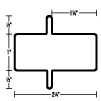

Our state-of-the-art pre-punched roll forming mill is capable of forming carbon steel tubes from coils with a minimum thickness of 1mm and a maximum of 3mm; and widths from 25mm to 400mm.

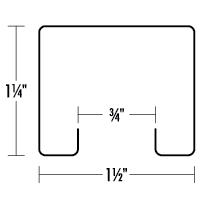

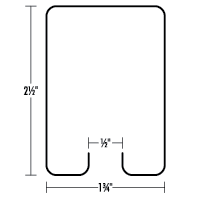

The variety of drilling patterns of this value-added process enables your parts to adapt to any project of the following markets:

Contact us to learn more about this value-added service.

Espesor Max. Max. Thickness | Ancho Max. Max. Width | Longitud de Corte Max. Max. Cut Length |

|---|---|---|

3.00 mm | 400.00 mm | 6000.00 mm |